The original and only certified solution

We are a leading manufacturer of patented concrete formwork systems.

K-Form’s mission is to revolutionise how the construction industry shutters concrete slabs. Our innovative shuttering system is expertly designed to save the building contractor time and money.

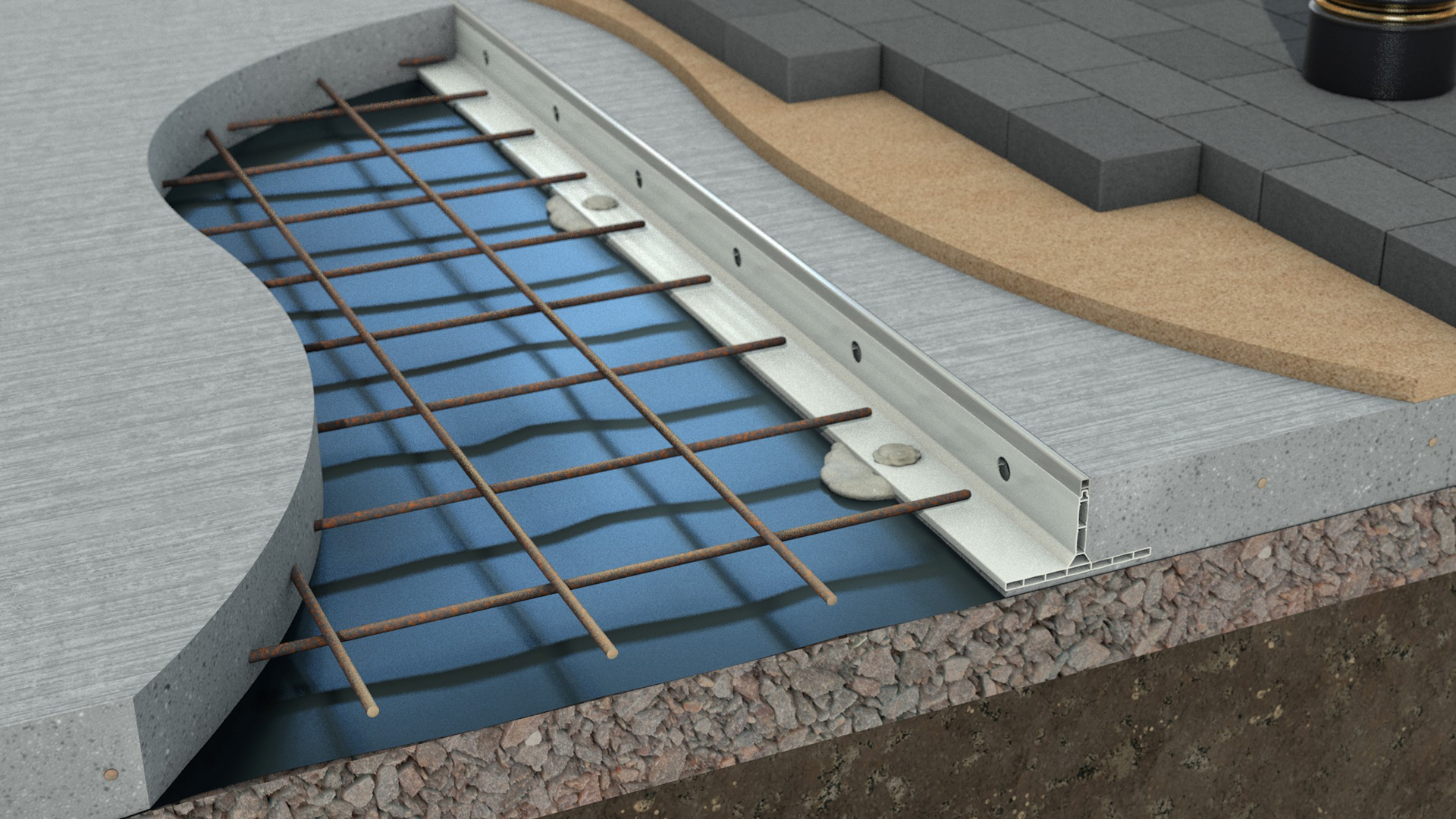

Patented Plastic Shuttering System

Made from 100% recycled uPVC

Saves Time & Money

BBA Certified

Manufactured using 100% recycled materials

Our Product Range

Extension Strip

The K85 Screed Rail

The K135 Screed Rail

Top Strip Angle Joint

Why choose K-Form?

Manufactured in the UK, K-Form’s patented concrete formwork system offers an innovative and sustainable plastic shuttering system that is designed to save you time and money.

K-Form works up to 4x quicker than traditional steel and timber shuttering systems.

The K-Form Way

Case Studies

Case Study

GE BE Transport

Case Study

Case Study

Case Study

Cribbs Causeway

K-Form – The Facts

01

2000s

Established in the early 2000s by construction industry veteran and pioneer, Peter Jaycock.

02

100%

K-Form is a patented shuttering system made from 100% recycled uPVC.

03

10x

10x faster installation compared to traditional metal or timber systems

04

3000+

Projects worldwide supported by KForm solutions

Frequently Asked Questions

Will K-form tip over when the concrete is being poured?

Does the top strip come out easily after the concrete has set?

Do I have to remove the top strip or can I leave it in?

TESTIMONIALS

Aaliyah Brown

CEO Industrium

Latest from K-Form

K-Form at Big 5 Construct Saudi!

Day 4 at Big 5 Construct Saudi! What an incredible three days it has been at Big 5 Construct Saudi! As we head into Day 4, our team is fully booked…

Wales In Middle East & North America (MENA)

Great to catch up with Peter Jaycock and Asli Sicilan from K-Form Screed Rails last week. A fantastic company from Bridgend who provide…

K-Form Welcomes UK-New Zealand Free Trade Agreement

Trade Deal will Support the Welsh Manufacturer’s International Growth BRIDGEND, Wales – 28 February, 2022— K-Form has today issued a statement…